Sugar

Wedge wire is used in different stages of sugar refining. Trislot® offers a complete range of solutions, making us your ideal partner.

Cones

Sugar is crystallized from concentrated massecuite and then spun in centrifugal machines to separate the pure sugar crystals from the massecuite

Wedge wire advantages

- Strong mechanical construction

- Longer lifetime

- No down time

- More revenue per ton of raw material because of continuous slots

Easy to install. Trislot delivers a plug and play construction

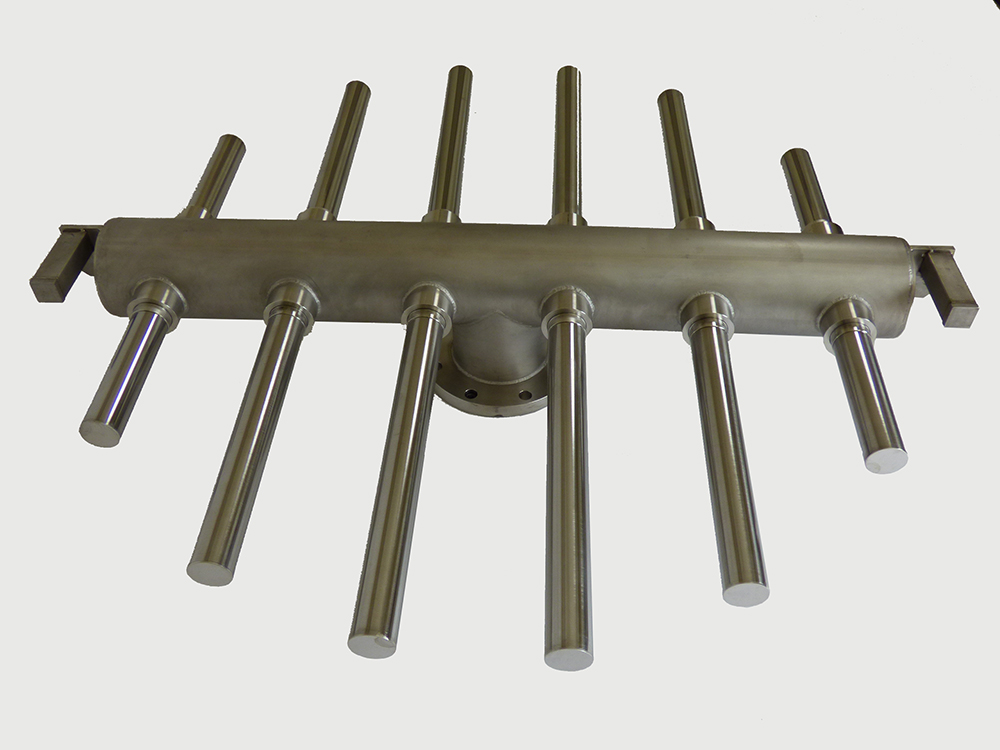

Pressure leafs

Wedge wire pressure leafs are used in the removal of calcium carbonate from sugar liquor. Pressure leafs require a large filter surface. Trislot is the only company world wide capable of producing screens with slots of 30 micron that are large enough for this application.

Technical details

- Slot opening : 0.03 mm and above

- Open area : minimum 3.8%

- Dimensions : screen is made to size

Wedge wire advantages

- Strong mechanical construction compared to conventional mesh

- Less risk of damage

- Larger open area

- Shorter filter cycles