Water

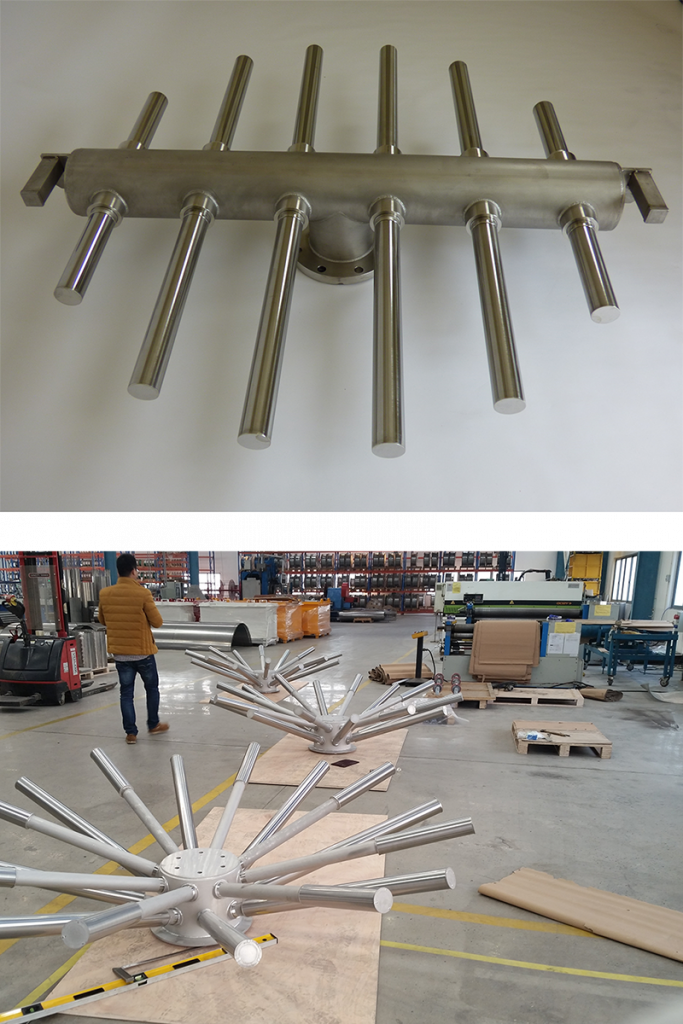

Nozzles

Wedge wire nozzles prevent the outflow of filter media, activated carbon or sand and secure an even distribution of water at the same time.

Advantages

- Long lifetime : When regeneration of active carbon is done at high temperature, plastic becomes brittle. Stainless steel nozzles are an excellent solution.

- Made to customer specifications

- Strong construction

- No clogging due to triangular slot

Distributor/collector

Ion exchange units and multimedia filters are often equipped with a distributor/collector. Trislot has extensive experience and expertise in designing the collector/distributor system for your needs. We can distinguish 2 types: a horizontal header with lateral connections or a central hub, installed vertically in the vessel with radial connections. The latter is usually used in smaller vessels. If you wish we can foresee a support construction or braces.

Technical details

- Materials : 316L, Duplex, Super Duplex, …

- Slot opening : 0.05-0.5 mm

- Pipe based laterals to ensure a perfect distribution

- Connection to header/hub can be either through threaded fitting or flange

Advantages

- Superb backwash ability and non-clogging

- Custom-made

- Excellent flow distribution

- Strong construction

- Low maintenance costs

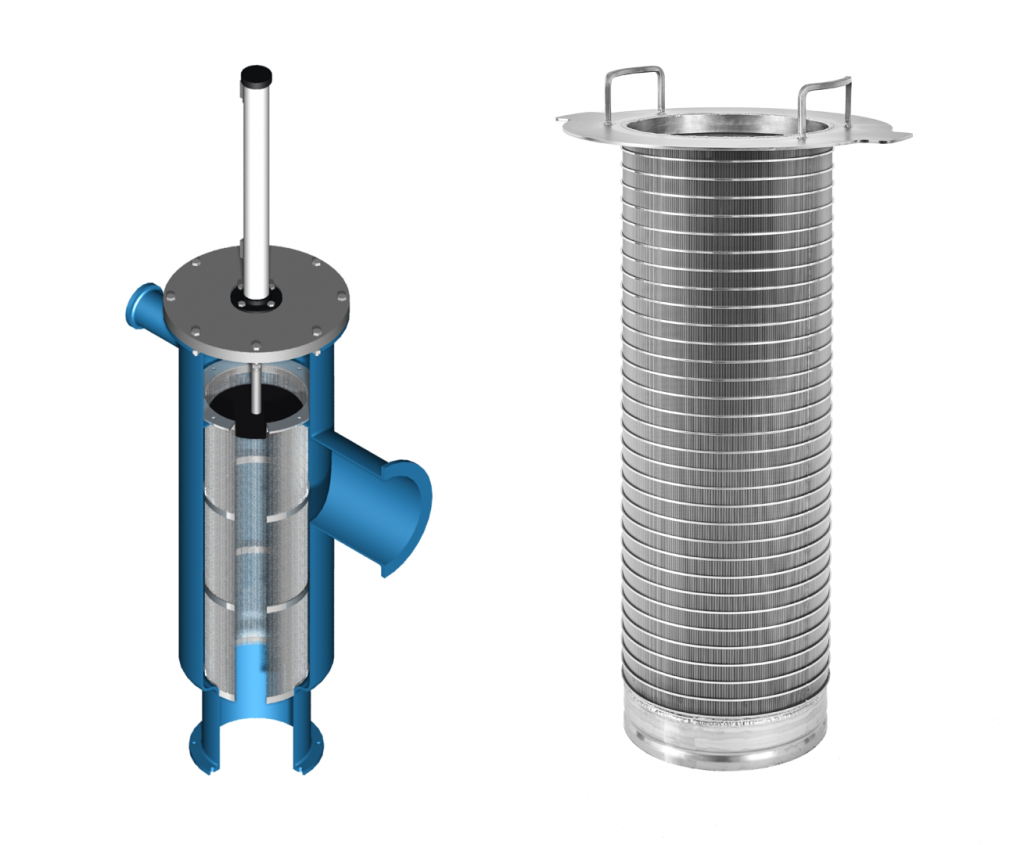

Resin traps and strainers

A resin trap or strainer serves to retain particles in a process flow. The quantity of the particles is in general very low so that cleaning can be done during flow interruption.

A resin trap is normally used to capture expensive resin that escapes from a treatment vessel by accident or to protect equipment further downstream.

A strainer is often used in tubes to block unwanted particles or dirt that would otherwise damage downstream equipment. Cleaning is carried out by removing the strainer from the tube.

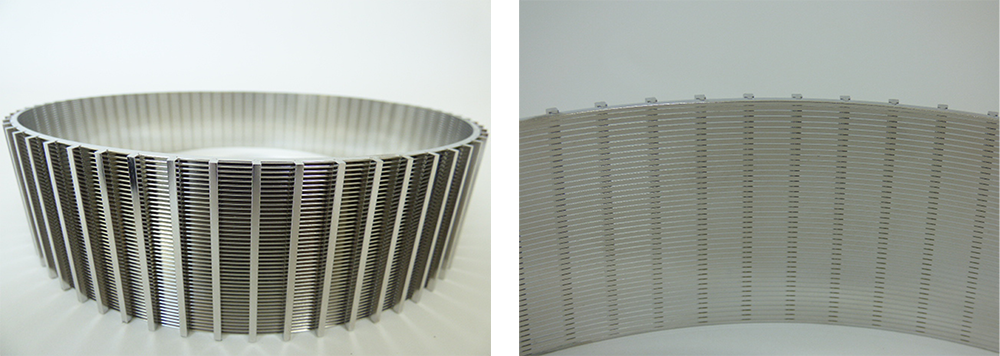

Slot tubes radial internal wire

Trislot’s ability to produce perfect roundness and tight tolerances in slot tubes, provides for a faultless interface between the screen surface and the rotating cleaning mechanism, be it a suction nozzle or brush.

Technical Details

- Materials : 304, 316L, Duplex, Super Duplex, SMO 254, Hastelloy…

- Construction : radial internal wire (FITO)

- Slot : 0.03 mm and above

- Diameter ranges from 150 – 1500 mm

- Can either be used as support medium for mesh or directly as a filtration unit

Advantages

- Wedge wire is n° 1 when it comes down to cleanability

- Mechanical strength

- No clogging

- No maintenance or replacement costs

Filter cartridges for automatic backwash

During the filter cycle the solids are deposited on the smooth surface of the filter element. A “cake” is built up and acts as an extra filter for the finer particles. The fines that slip through, do not become lodged within the conical slots.

By reversing the flow, the cake and dirt are removed from the filter surface. This is the backwash cycle.

The most common flow used for the filter cycle is in to out.

Technical details

- Materials : 316L, Duplex, Super Duplex, SMO 254, Hastelloy, Monel 400…

- Construction : radial external wire (FITO, flow out to in is also possible) or axial internal wire (FITO)

- Slot : 0.025 mm and above

- Diameter : 25 mm and above

Wedge wire advantages

- Wedge wire is n° 1 when it comes down to cleanability

- Mechanical strength

- No clogging

- No maintenance or replacement costs

Slot tube for self cleaning filter

A slot tube where the slot runs in the axial direction, with smooth surface on the inside can be cleaned by a suction plate, a scraper or by Bernoulli effect.

Technical details

- Construction: axial internal wire FITO

- Slot: 0.015 mm and above

- Diameter: 25 mm and above

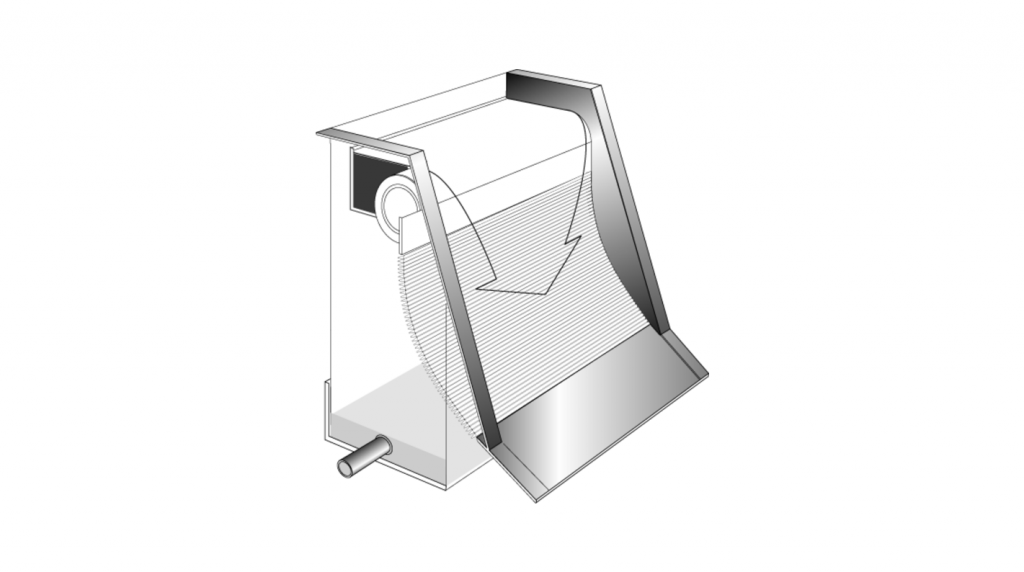

Sand bed screens (SBM)

An air distribution system is positioned on the bottom of the vessel. The screens (employing the unique anti clogging characteristics of the V-wire profiles) are positioned on top of this and support the sand bed. Sand filtration is frequently used and is a very robust method to remove suspended solids from water. The filtration medium consists of a multi layered sand bed with a variety of sizes and specific gravities. When the sand bed is saturated with particles, the flow direction can be reversed and combined with a uniform air flow to agitate the sand bed and clean the filter.

Advantages

- Uniform air flow without dead zones

- High mechanical strength

- Custom made solutions (also for revamps)

- Complete stainless steel construction

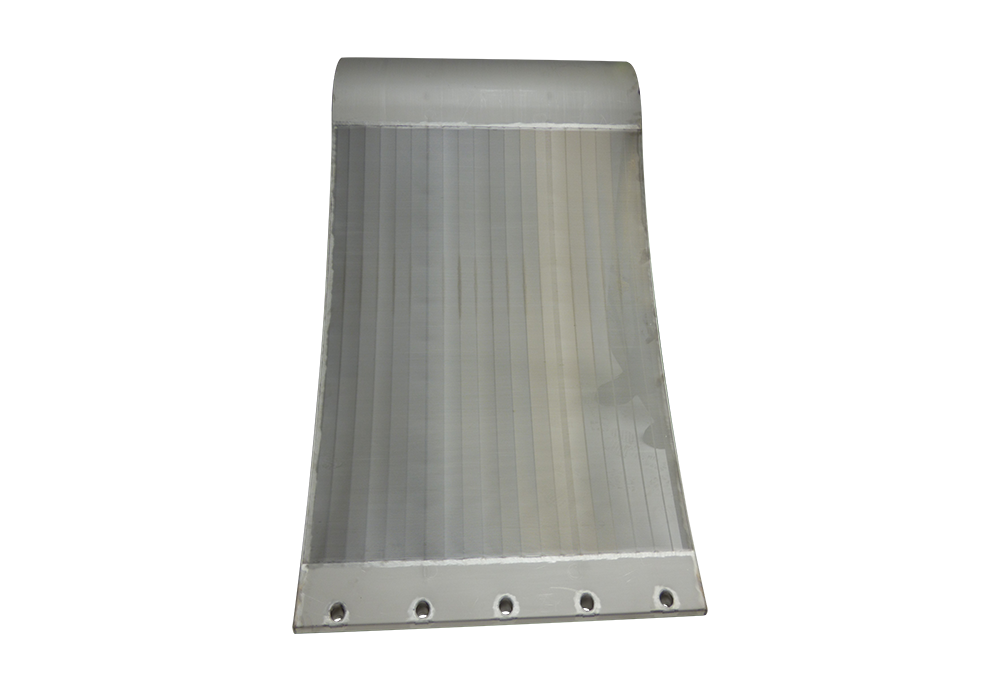

Sieve bends

Wedge wire screens are produced flat and are then curved to the desired angle and radius. If the customer desires, a tilt can be applied when welding the surface wires for extra dewatering capacity.

Intake screens

Coanda screens

Coanda screens are intake screens that are installed in a river or creek. They retain leaves, small branches etc. These wedge wire intake screens are common for hydro plants.

Cylindrical intake screens

While Coanda screens are installed just beneath the water surface, cylindrical intake screens are fully submerged. They retain larger particles and water life floating in the river and protect pumps and installations further up the production line. The controlled lower slot velocity along the screen surface also reduces the likelihood of impingement and entrainment of marine life.

This type of intake screen also has the ability to be cleaned using an air backwash system whereby a controlled burst of compressed air is deployed.