Radial external wire

Radial external wire

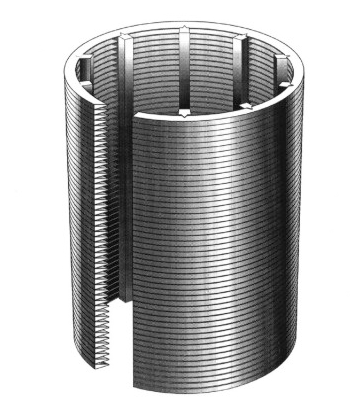

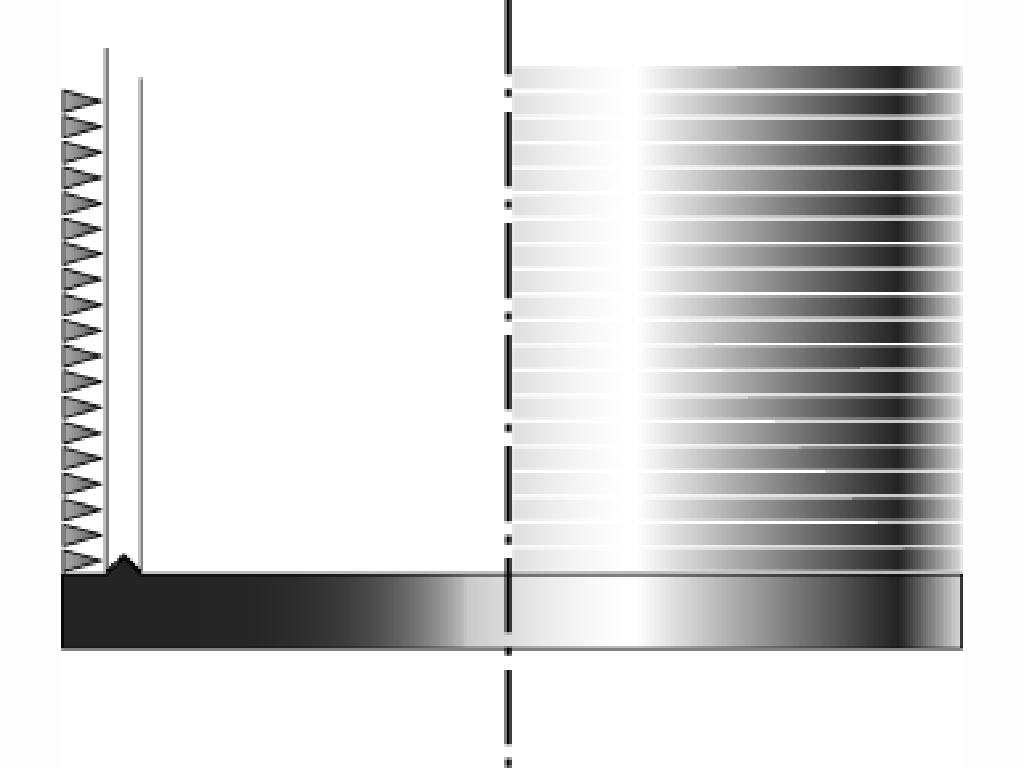

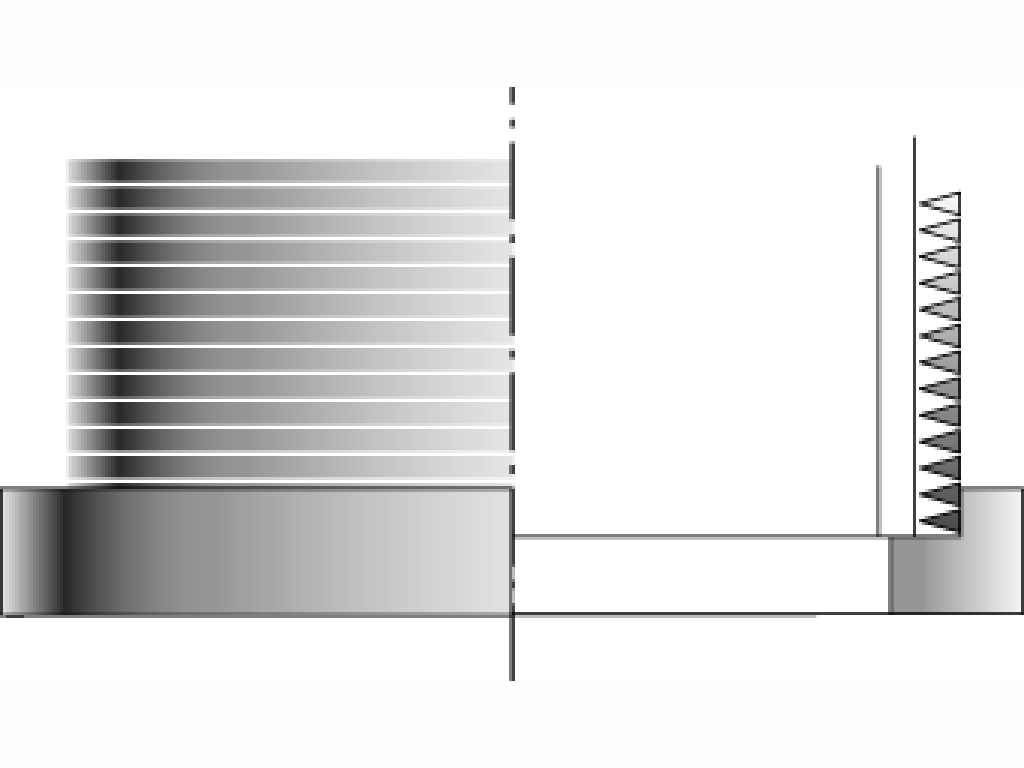

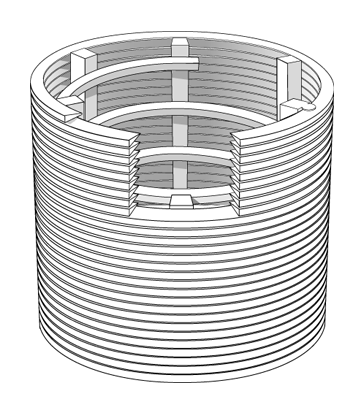

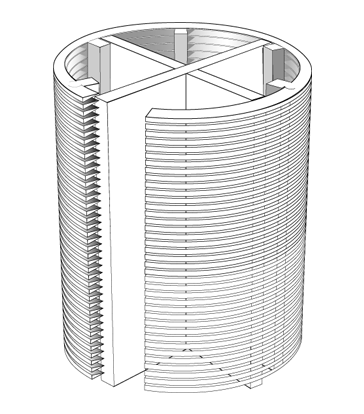

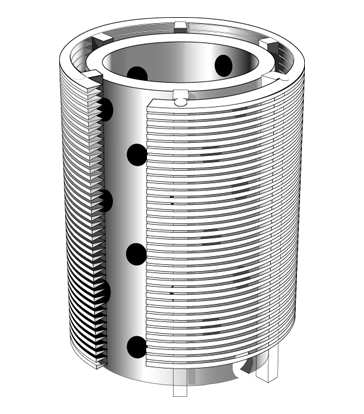

These tubes are composed of a surface profile wire that is spirally wrapped around axial support profiles and attached to each other by resistance welding.

There are 2 types:

Direction

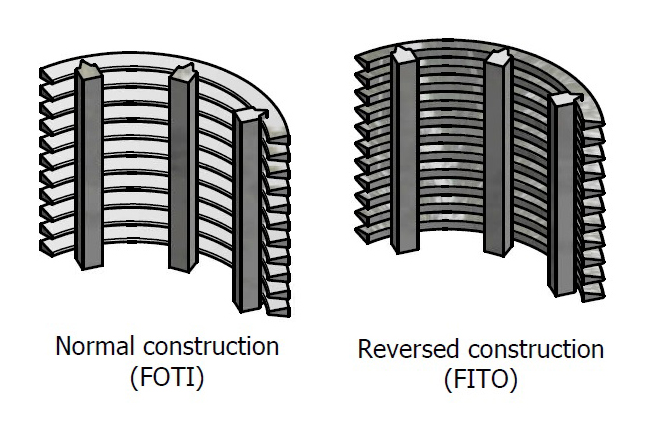

The direction of the filtering flow determines the position of the surface profiles in relation to the support profiles.

- The flat side of the surface profile is on the outside of the tube when the flow is from out to in (FOTI)

- The flat side of the surface profile is on the inside of the tube when the flow is from in to out (FITO). This is also called a reversed profile.

Possibilities

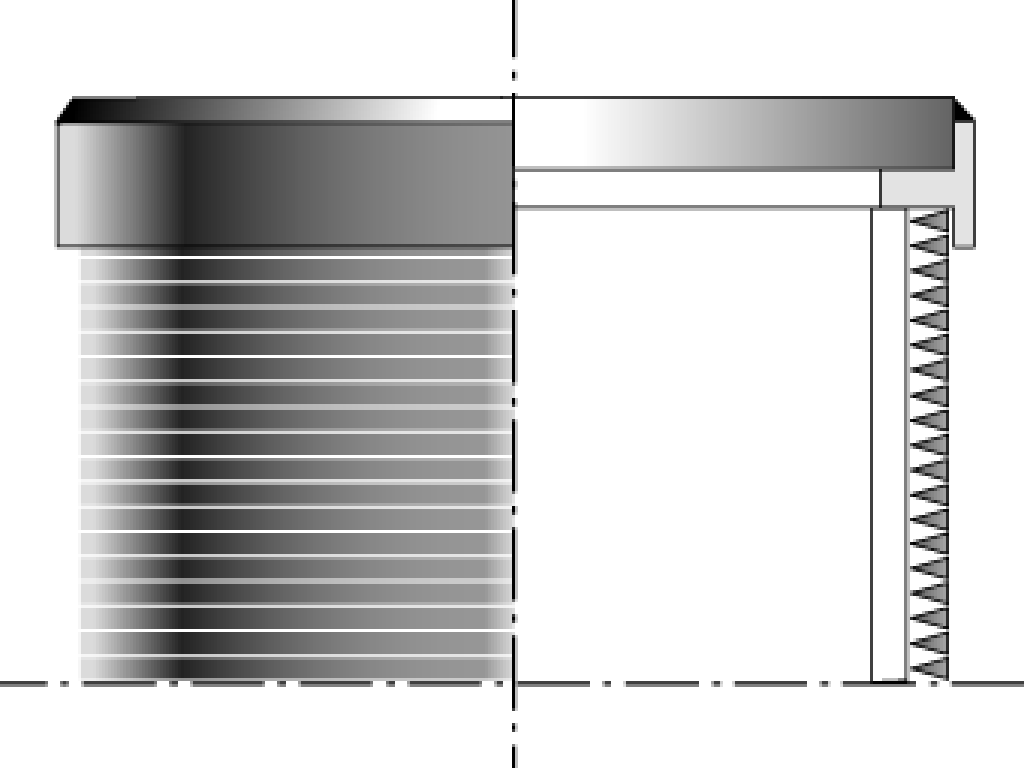

The designation of a slot tube with radial external wire describes its construction as follows:

Surface wire / Support wire x number of support wires

Example: 12S/Q25 x 8

This means that the profile wire is 12S. The support wire is Q25 and there are 8 support wires, equally spaced around 360°

Standard constructions (1)

| Profile | Support wires | Min. diameter | Min. slot width (2) |

|---|---|---|---|

| in mm | in mm | ||

| 4S | Q22 or Q25 | 20 | 0.015 (3) |

| 5S | Q22 or Q25 | 20 | 0.015 (3) |

| 6SC | Q22 | 20 | 0.015 (3) |

| 10S | Q25 | 20 | 0.015 (3) |

| 11S | Q22 or Q25 | 21 | 0.015 (3) |

| 12S | Q25 | 21 | 0.015 (3) |

| Q35 | 30 | 0.05 | |

| 18S | 22S or Q35 | 30 | 0.05 |

| Q25 | 25 | 0.03 | |

| D45 | 300 | 0.2 | |

| 10x3 | 300 | 0.2 | |

| 22S | 22S or Q35 | 45 | 0.05 |

| D45 or 10x3 or 25x3 | 300 | 0.2 | |

| 28S | Q35 | 215 | 0.2 |

| D45 or 10x3 or 25x3 | 300 | 0.2 | |

| 34S | Q35 | 300 | 0.2 |

| D45 or 10x3 or 25x3 | 300 | 0.2 | |

| 42S | Q35 or D45 | 300 | 0.2 |

| 10x3 or 25x3 | 300 | 0.2 |

(1) Special constructions are possible on request

(2) The minimum slot will increase when the diameter becomes bigger

(3) Depending on the slot tube diameter

Standard finish of the slot tubes:

- Grinding of the end surfaces

- Removal of loose profile ends

Standard tolerances:

| Diameter < 164 mm | +/- 0,3 mm | |||

| Diameter >= 164 mm - <= 301 mm | +/- 0,5 mm | |||

| Diameter > 301 mm | +/- 2,5 mm | |||

| Length for OD <= 301 mm | +/- 2 mm | |||

| Length for OD > 301 mm | +/- 4 mm |

Special features

Variable slot openings are possible on all diameters

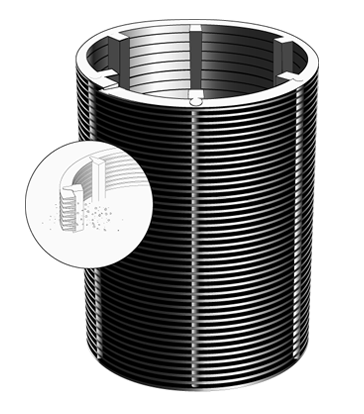

Continuous cylinders: by using a lot of support profiles, an axial slot can be obtained. These filter elements are called continuous cylinders.

Optional finish for the slot tubes:

- Degreasing and pickling

- Fastening of loose profile ends

- Post machining for tighter tolerances

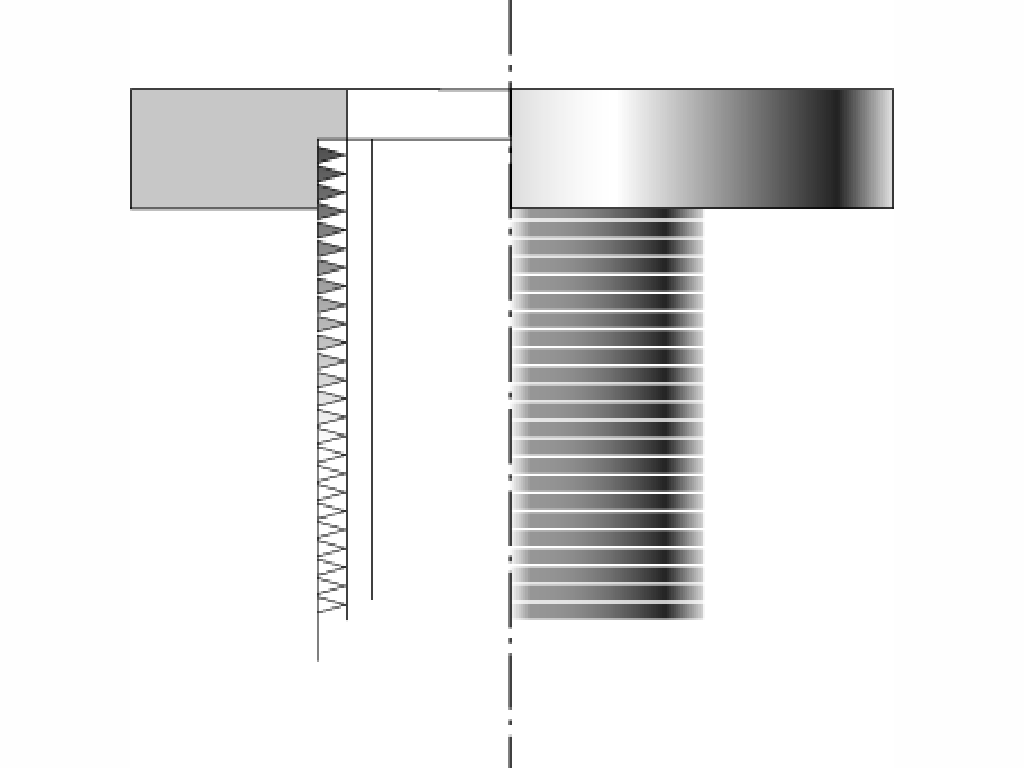

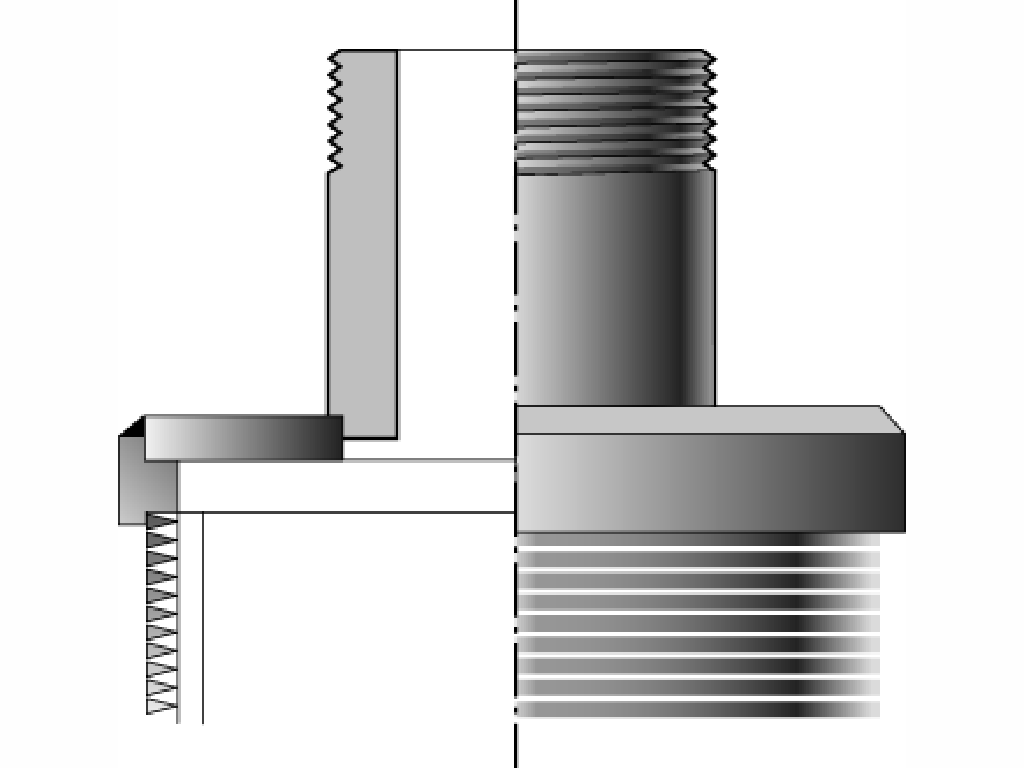

Slot tubes with end pieces:

Standard end pieces are always welded onto the support profiles. Other custom made end pieces can be fabricated on demand.

To protect slot tubes against collapse, reinforcements are optional.

Reinforcing a slot tube is possible through:

- More or stronger support wires

- By adding internal reinforcement

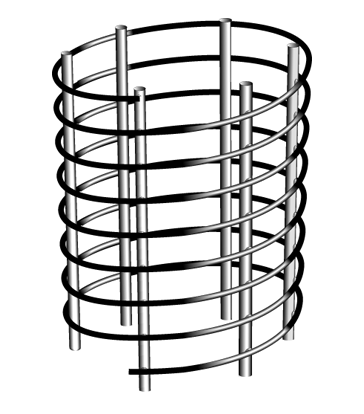

Support elements

If the slot tubes are used as a carrier for another filter medium, for example textile, round wire can be applied. These support elements can be welded with 1, 2 or 3 wires next to each other.

Technical information

- Diameter: ± 25 to 40 mm

- Standard profiles

- Spiral wire: Ø 0.8 mm

- Support wire: Ø 2 mm

Compared with conventional support elements (such as perforated tubes, wire mesh,…) Trislot support elements have the following advantages:

- A smaller contact between the support tube and the filter media results in a more active filter area, which creates a larger active filter media and a lower pressure drop.

- Thorough cleaning by back flushing is possible.

- Strong mechanical constructions

- Larger open area