Axial internal wire

Axial internal wire

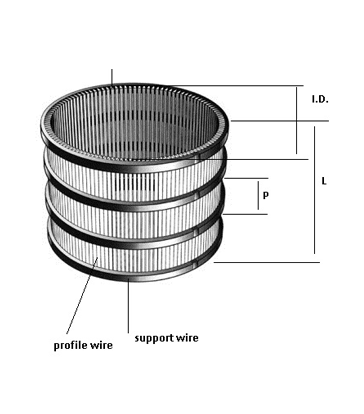

This type of filter tube is characterized by an axial profile wire/axial slot direction. The support wire is oriented on the outside of the filter element in a radial direction. The smooth surface of the profile wire is on the inside and the filtration direction is therefore from the inside to outside. Although FOTI is also possible in exceptional cases.

Possibilities

The designation of a slot tube with axial internal wire describes its construction as follows:

Surface wire / Support wire – distance between the support wires (center to center) also called the pitch

Example: 12S/Q25 – 17

This means that the profile wire is 12S. The support wire is Q25 and the pitch, space from center to center of the support wires, is 17 mm.

A slot tube with axial internal wire consists of one or more flattened slot tubes with radial external wire or flat welded screens, rolled to form and welded together. This type of filter element therefore typically has one or more welding seems.

This type of slot tube is generally used in conjunction with a screw or scraper blade or suction plate on the inside, which cleans the filter element.

The minimum internal diameter is 25 mm. The maximum diameter is unlimited and a wide range of lengths can be provided on demand.

Just like slot tubes with radial external wire; end pieces, reinforcements or special fittings can be welded to the tubes to suit the customers needs.

Standard tolerances:

| Diameter <= 100 mm | +/- 1 mm | |

| Diameter > 100 mm - <= 200 mm | +/- 1,5 mm | |

| Diameter > 200 mm - <= 400 mm | +/- 2 mm | |

| Diameter > 400 mm - <= 1000 mm | +/- 3 mm | |

| Diameter > 1000 mm | +/- 4 mm | |

| Length <= 200 mm | +/- 2 mm | |

| Length > 200 mm | +/- 4 mm |

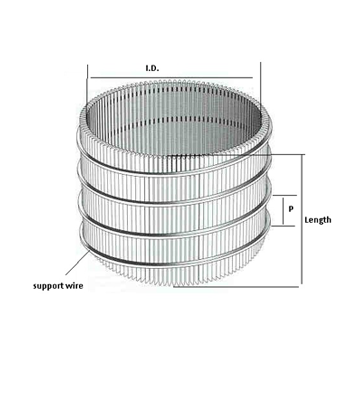

Special execution: Continuous support

In some cases the above mentioned construction can be manufactured directly on machine without a welding seam. The support wire is than continuously wrapped around the surface profiles.