Oil & Gas

Trislot has a wide range of wedge wire reactor internals available for your media retention and solid-liquid separation processes.

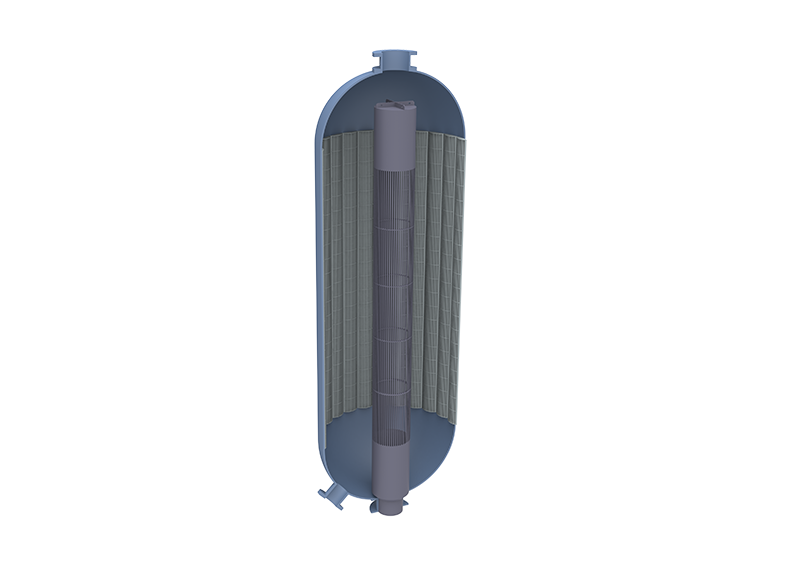

Radial flow

The flow of the process liquid or gas through the catalyst is from outside to the center of the reactor and vice versa. These reactor internals are employed for their high-volume flow capacity with minimal pressure drop.

Scallops

These are D-shaped screens manufactured from wedge wire screens. These scallops are positioned against the reactor wall by means of expander rings.

Advantages

- Higher surface area than the traditional outer screen

- Easy installation and repair due to individual screens

- Can be held in stock as spare parts

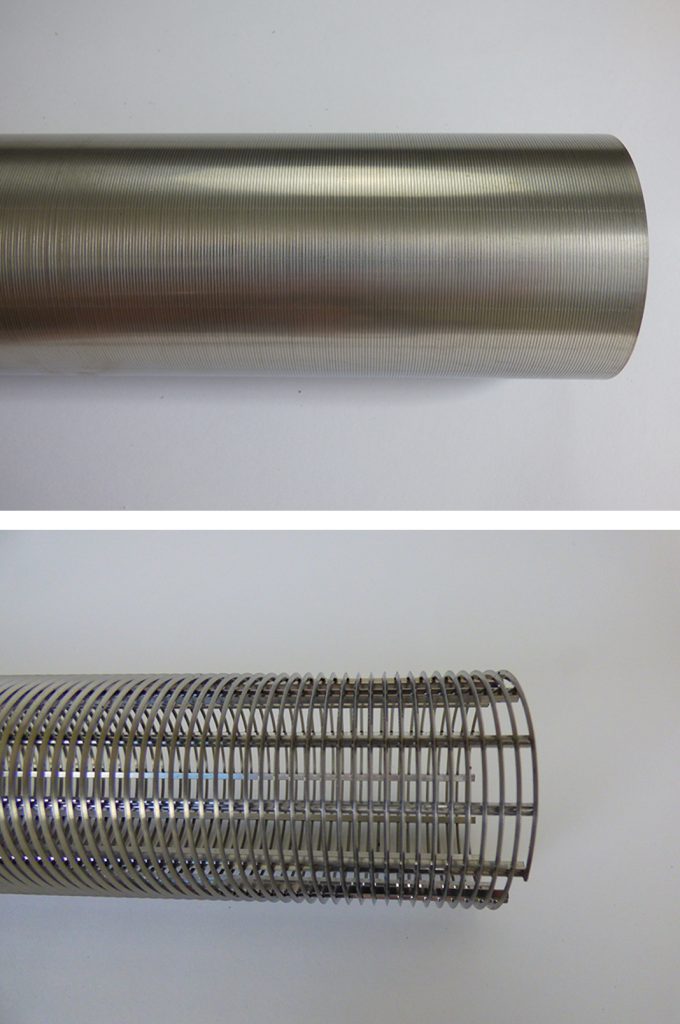

Center pipes

These can be made of cylindrical screens or screens wrapped around a strong perforated tube. They are designed for a calculated design load and pressure drop through the catalyst bed.

Outer basket

These can be made of cylindrical screens (axial internal wire) or by welding a number of screen segments. Usually, additional reinforcement is necessary. Mainly used for high-volume flow.

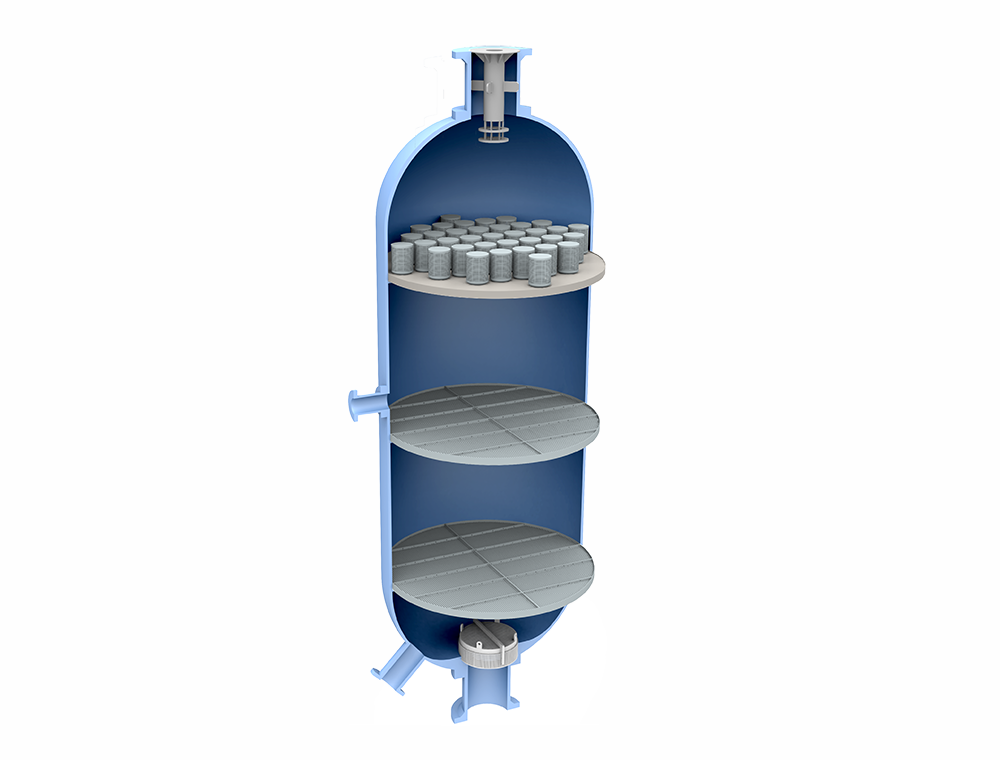

Axial flow

The internals for this type of reactors are chosen for their high ability to safely retain your expensive catalyst media from migration.

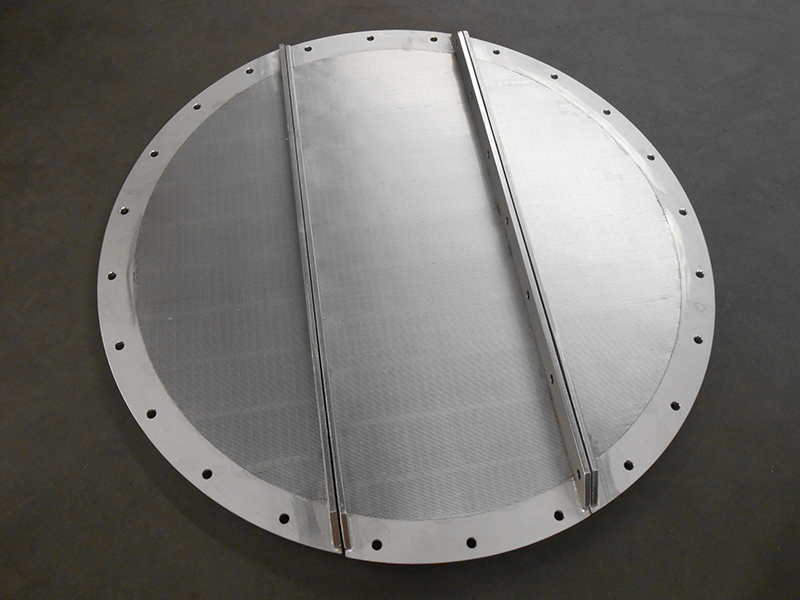

Catalyst support grids

These are flat welded screens used for directly retaining media. They are designed in such a way that they can pass through the vessel manway and can carry the design load which includes the bed weight and pressure drop through the catalyst/resin bed. If desired Trislot can also provide support beams.

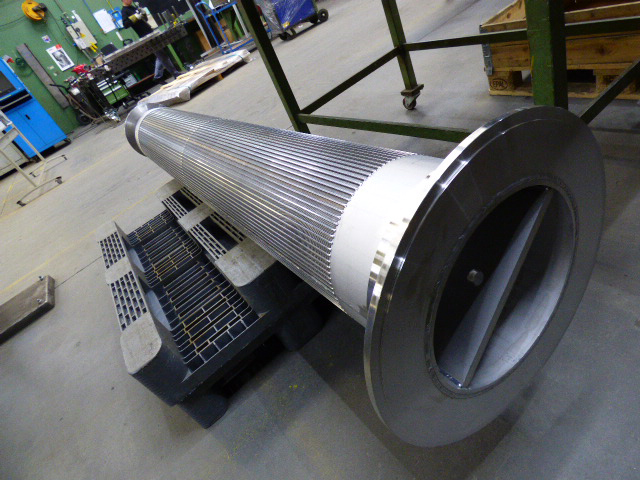

Outlet collectors

Also known as bottom baskets. They are used for direct media retention and as a safety screen to prevent migration of catalyst through the outlet nozzle. They are designed in such a way that they can pass through the vessel manway and can have either a screen or plate top.

Inlet distributors

These wedge wire screens are used to evenly distribute the process flow over the top surface of the catalyst bed or onto the adjacent reactor internal (eg distribution tray)

Filter elements

Also known as scale trap baskets. They are a series of cylindrical screens arrayed at the top of the upper catalyst bed. They collect metallic contaminants or scale from the inlet flow. Filter elements also increase the total surface area of the upper catalyst bed and extends the bed’s useful life.

Processed and injection water

Because of its high open area and non-clogging characteristics, wedge wire is an excellent choice for the treatment and filtration of injection/produced seawater in multi-media vessels.

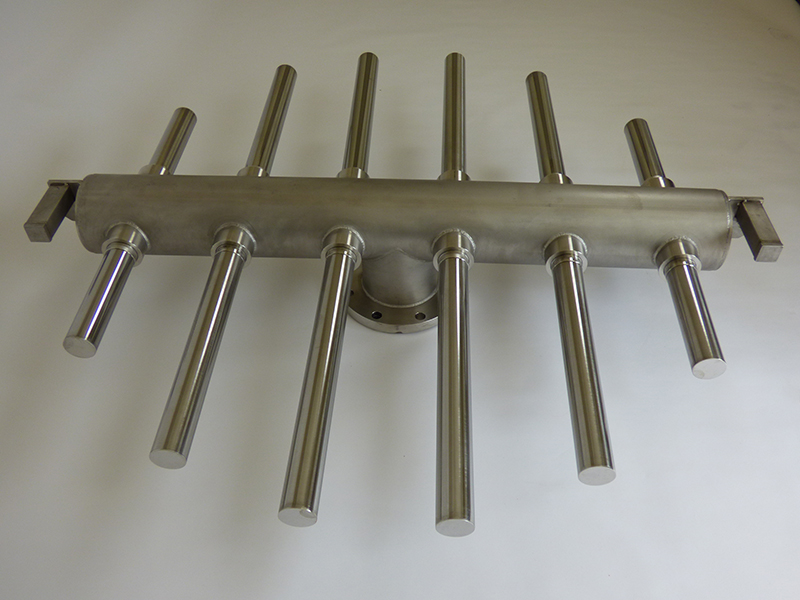

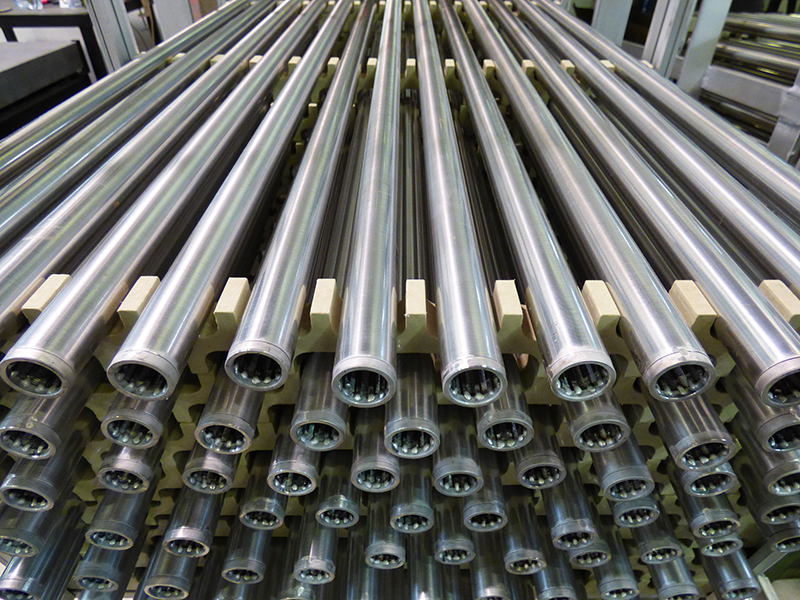

Laterals

Compared to other solutions this collector system guarantees that there are no dead zones in collecting the fluid which means a more efficient filtration

Technical Details

- Alloys : 316L, Duplex, Super Duplex (UNS32550/UNS362750-60), …

- Slot opening : 0.05-0.5 mm

- Flow out to in

- Diameter slot tubes : 25 mm and above

Advantages

- Superb backwash ability and non-clogging

- Custom-made

- Excellent flow distribution and media retention

- Strong construction

- Low maintenance costs

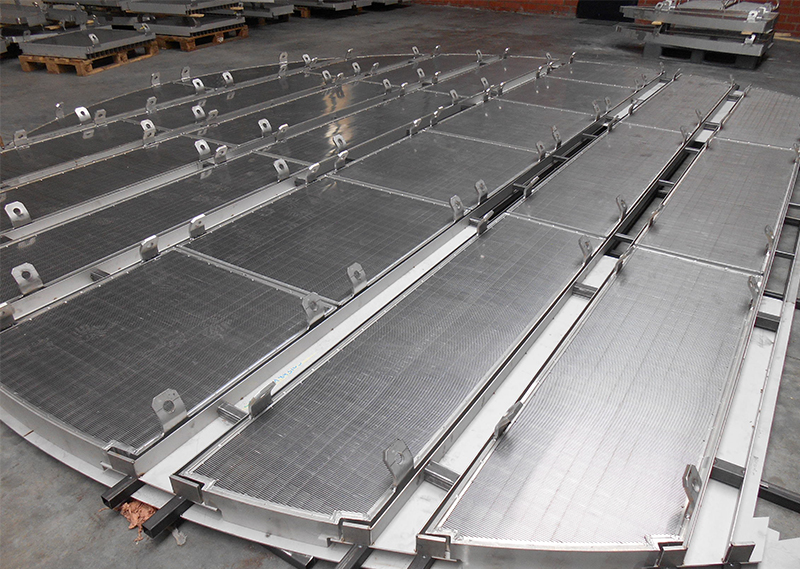

Multimedia filter bottoms

To allow reinjection of produced seawater into the source, all suspended solids, hydrocarbons and oily residues need to be filtered out.

Advantages

- More open area => shorter cleaning cycle

- Superb backwash ability and non-clogging

- Custom-made

- Excellent flow distribution and media retention

- Rigidity

- Long service life

- Low maintenance costs

Scrubber tubes

The scrubber filter element is used in a key-process of backwashing & fluidization of the nutshell media as its performance dictates the removal of trapped oil and other particles.

TRISLOT wedge wire scrubber tubes use low energy input and short backwash cycle time due to the high open area ratio and excellent roundness.

Technical details

- Flow can be FITO or FOTI

- Construction can be axial internal, radial internal or radial external wire

- Open area : 14%-25%

- Material : 316L, Duplex, Super Duplex, …

Advantages

- High open area allows a short backwash cycle time

- Rigidity. Wedge wire has sufficient mechanical strength of its own, it does not need a support

- Excellent flow distribution and media retention

Others

Coal gasification

Chemically breaking down coal to fuel gas is called gasification. This is an extremely demanding process for the filter elements as the filtration takes place under very high pressures and temperature. That is why wedge wire is an excellent filter medium for this process. Wedge wire can either be used as filter medium or as a support structure for other filter media.

Feedstock filtration

Wedge wire screen elements are employed in this filtration system to remove contaminants such as coke particles and scale rust from sour water, reactor feeds and hydrocracker feeds.

Technical details

- Slot size : 0.015 -0.05 mm

- Open area : 2% – 4.8%

- Construction : radial external wire – FOTI

Advantages

- Strong mechanical construction

- Non-clogging

- Easy to clean through backwash