Flat screens

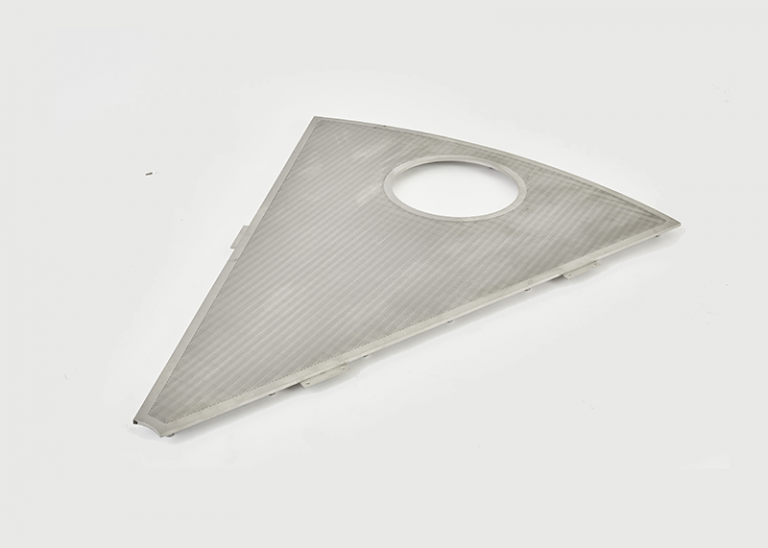

Flat screens

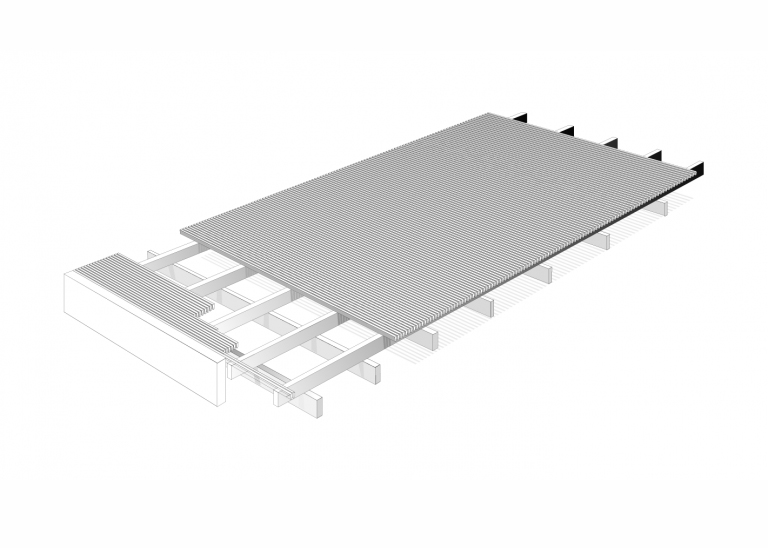

Trislot flat screens are flat filter surfaces that can be manufactured in two different ways.

- Welded screens: directly made on the flat welding machine

- Flattened slot tube: manufactured by opening and flattening a slot tube with radial external wire

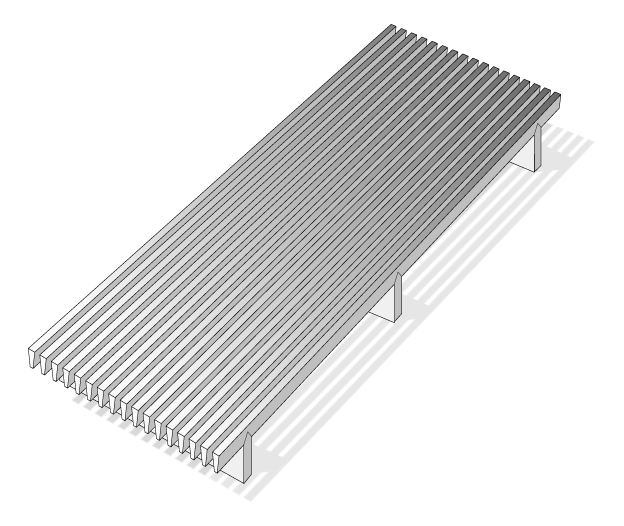

Welded screen

Trislot welded screens are produced directly on a machine by welding surface profiles onto support profiles at each intersection at 90° angles.

Advantages of manufacturing directly on a machine:

- Enhanced profile wire flatness: no profile wire waviness between support wires

- Avoids the weakening of the welds and the chance of stress corrosion that can result when producing from a slot tube

- Accurate distance between support profiles

- Possibility of different support wires in one screen

- Flexibility to have variable spacing between support wires in one screen

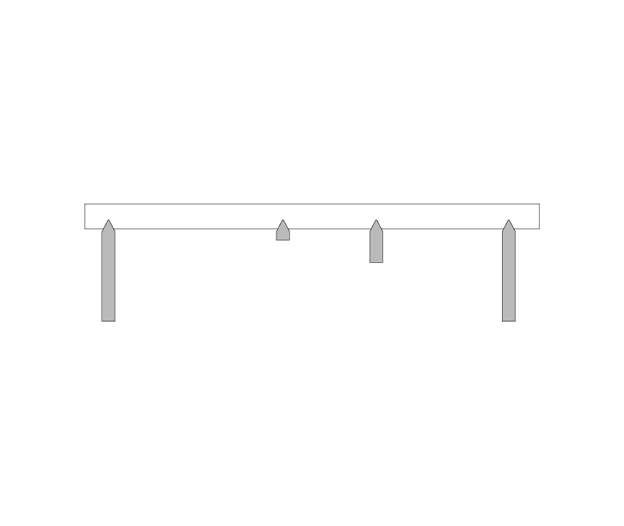

Flattened slot tube

Depending on the required specifications, we can also opt to produce from a slot tube. Subsequently the tube is split open, flattened and cut to the required size.

Possibilities

The designation for a flat screen is as follows:

Surface wire / Support wire – distance between the support wires (center to center) also called the pitch

Example: 22S/10×3 – 70

This means that the profile wire is 22S. The support wire is 10×3 and the pitch, space from center to center of the support wire, is 70 mm.

Standard constructions (1)

| Profile | Support wires | Min.slot | Standard pitch (P) |

|---|---|---|---|

| in mm. | in mm. (2) | ||

| 11S | Q25 | 0.03 | 17/22 |

| 12S | Q25/Q35 | 0.03 | 17/22 |

| 10X3 | 0.1 | 17/25 | |

| 18S | Q35 | 0.05 | 17/25 |

| Q35/10X3/25X3 | 0.1 | 25/70 | |

| 22S | Q35 | 0.05 | 17/25 |

| Q35/10X3 till 50X3 | 0.12 | 25/70 | |

| 28S | Q35/10X3 till 50X3 | 0.15 | 17/25/70 |

| 34S | Q35/10X3 till 50X3 | 0.15 | 17/25/70 |

| 42S | Q35/10X3 till 50X3 | 0.15 | 17/25/70 |

| 50S | 10X3 till 50X3 | 0.15 | 70 |

(1) Special executions are possible on request

(2) In most cases, all pitches are possible

Standard tolerances:

| Length and width <= 500 mm | +/- 2 mm | |||

| Length and width > 500 mm <= 1500 mm | +/- 3 mm | |||

| Length and width > 1500 mm | +/- 4 mm |

Maximum dimensions

| Max. surface profile length | Max. support profile length | |

|---|---|---|

| Pitch 17mm / Profile Q25 | 1300 mm | 2000 mm |

| Pitch 17-25mm / Profile Q35 | 2700 mm | 3000 mm |

| Pitch 22mm | 710 mm | 1650 mm |

| Pitch ≥ 70mm | 3000 mm (3) | 3400 mm |

(3) Depending on pitch

Standard finish for flat screens

- Flattening

- Cutting width and length

to fit the required size.

Optional finish for flat screens

- Deburring

- Degreasing and pickling

- Post-machining for tighter tolerances

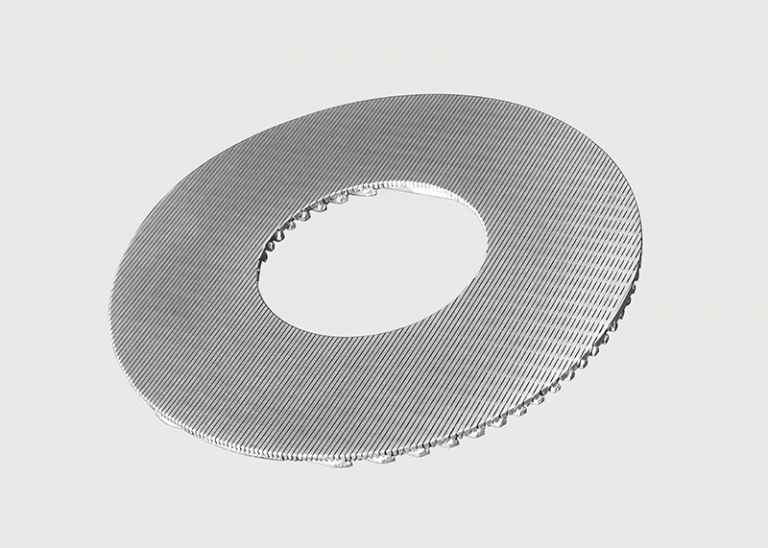

Applications

- Catalyst support grids

- Vibrating screens, dryers and coolers

- Beer bottom

- Oil extraction

- Architecture