Paper & Pulp

Coated paper requires filtering in different stages of the production . Wedge wire is the ideal medium because of the high open area, roundness and high cleanability.

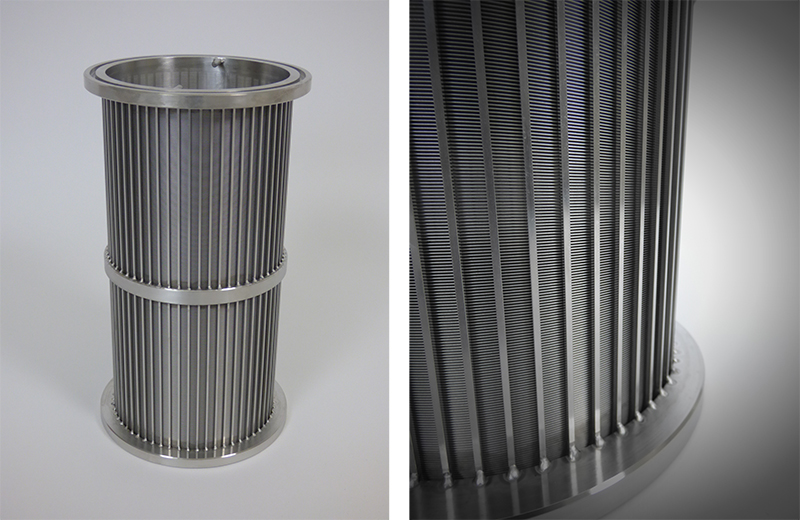

Slot tubes radial internal wire FITO

The construction of these wedge wire tubes makes them easy to clean by a scraper on the inside. Trislot guarantees perfect roundness.

Technical details

- Construction : radial internal wire FITO

- Typical diameter : from 200 – 500 mm

- Open area : 12% and above

Slot tubes radial external wire FOTI

Contaminants need to be filtered out of liquids, coating pigments or colours. They are cleaned by scrapers on the outside. Trislot guarantees perfect roundness of the slotted tubes to facilitate cleaning by the scraper.

Technical details

- Construction : radial external wire FOTI

- Slot sizes : 0.05 mm and above

- Open area : 5% and above

Advantages

- High slot precision

- Trislot can produce small slots and fine profiles in large diameter slot tubes

- Higher open area compared to perforated plate

- Non-clogging

- Easy to clean

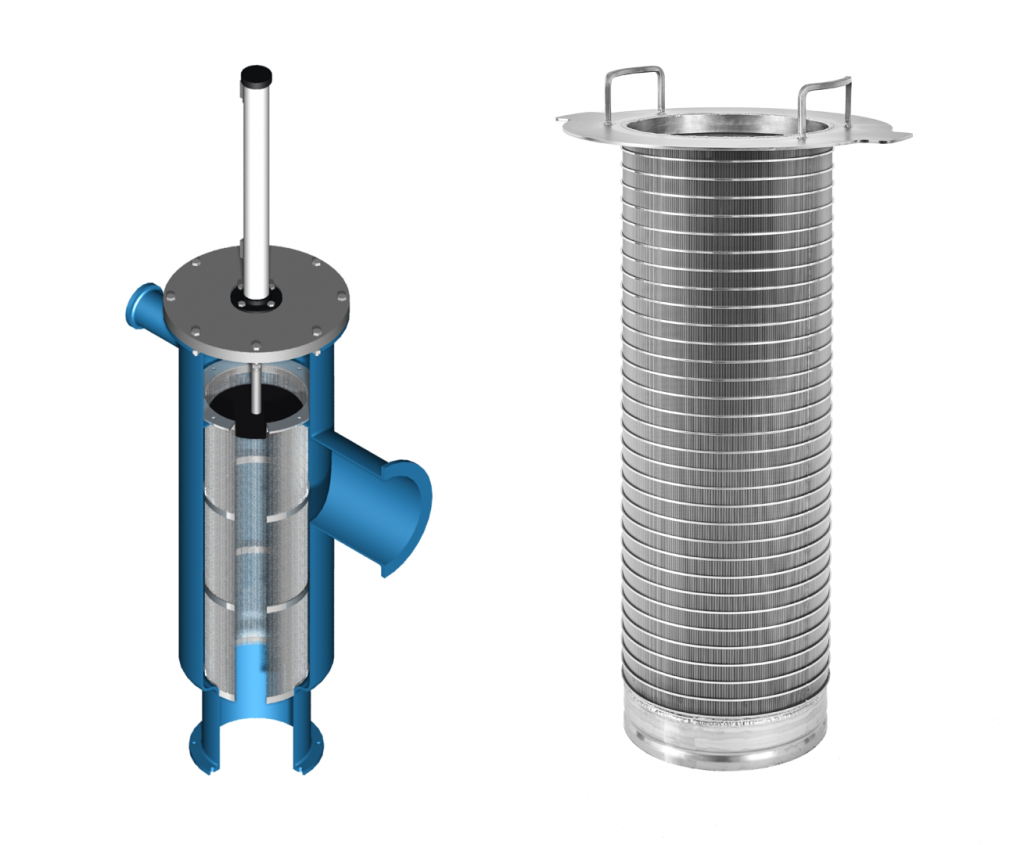

Slot tube for self-cleaning filter

A slot tube whereby the slots run in the axial direction, and thus creating a smooth surface on the inside that can be cleaned by a suction plate, a scraper or by Bernoulli effect.

Technical details

- Construction : axial internal wire FITO

- Slot : 0.015 mm and above

- Diameter : 25 mm and above

Screw presses

Screw presses dewater pulp fiber and sludge. The screw press can increase the dry matter by up to 30%.

Technical details

- Construction : axial internal wire FITO

- Support wire is positioned on the outside, either as a ring or as a spiral (continuous construction)

- Special shaped support wire is used to avoid fibers becoming trapped.

Advantages

- Strong construction

- Non clogging surface

- Perfectly round cylinder

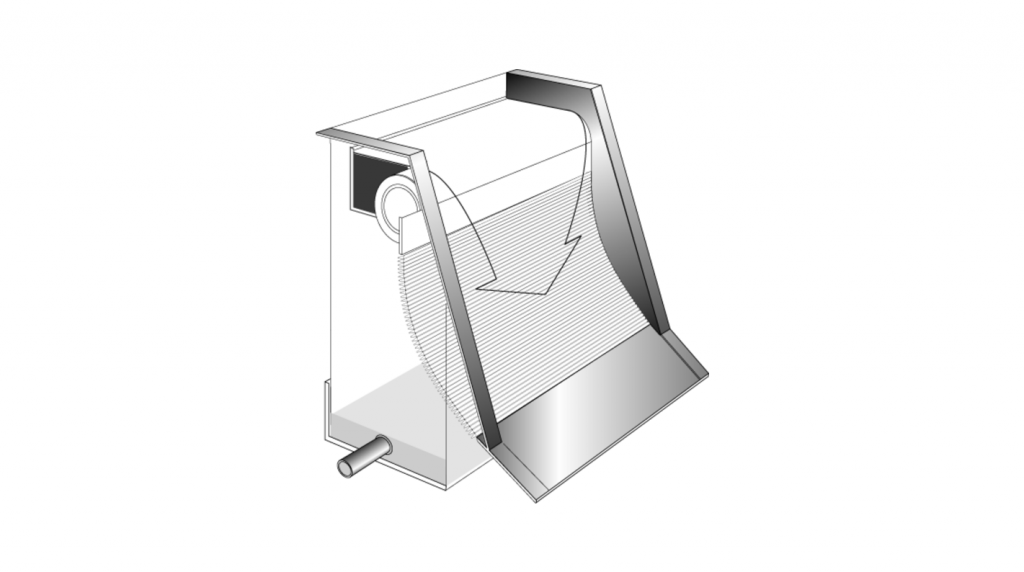

Curved screens

Curved screens are used to remove contaminants in feedstock with a minimal loss of fibers . Pressure screens are the final filtering stage before the headbox.